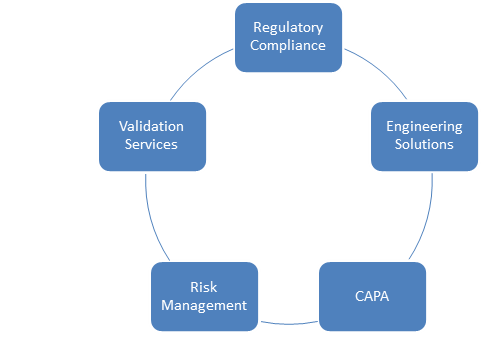

We offer individual specialists and project teams to assist clients with process design, protocol development, quality improvement, auditing, and operational review to achieve compliance with FDA regulations, CE marking, and other regulatory body requirements. We are particularly well suited for event driven work such as remediation efforts, responses to 483(s), CAPA's, quality system improvement plans (QSIP), new product releases, and qualifying and validating new manufacturing equipment.

- Gap Analysis

- Preventative Maintenance

- Manufacturing Procedures

- Equipment Drafting

- Quality Procedures

- Sampling Plans

- Tool Specifications

- Product Transfer

- Six Sigma

- Cost Reduction Strategies

- Process Optimization/ Improvement

- Compliance Auditing and Remediation

- Technical Files

–Facilities & Utilities Commissioning and Validation

–Utilities IQ/OQ/ PQ

–Equipment IQ/OQ/ PQ

–Test Method

–Product & Process

–Computer System (CSV)

–Software

–Master Validation Plan